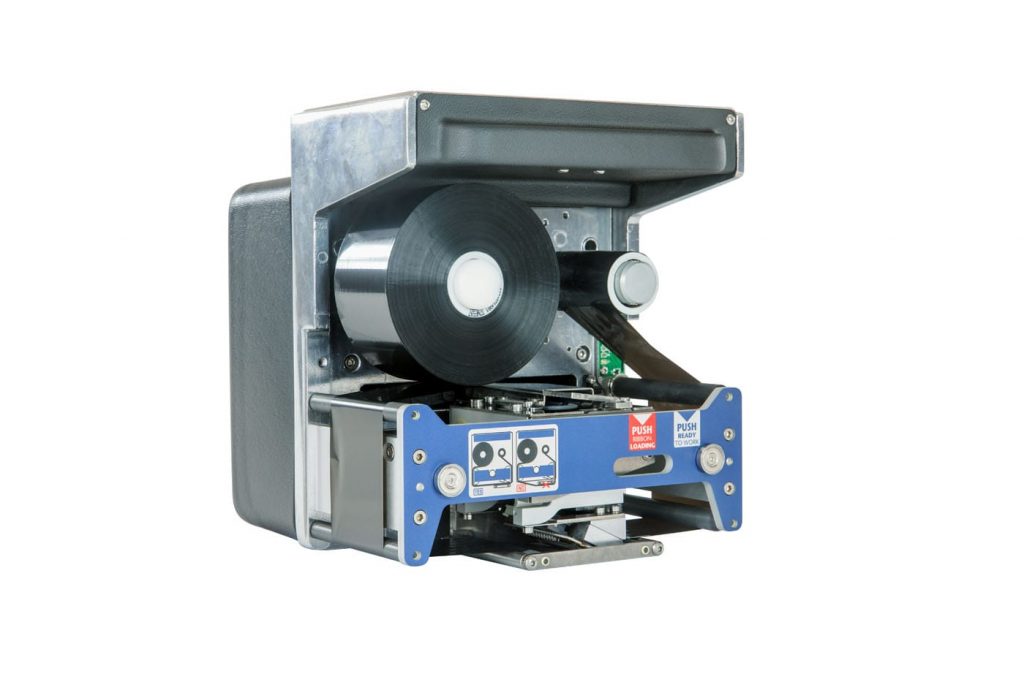

This SWING model is ideal to be integrated on intermittent multi-track or large area packaging machines. With its ready-for-use bracketing system, the Swing can print directly on the production or packaging line without needing to change the plate.

SWING XL 4.09 – Printing area: 107 x 90 mm

SWING XL 4.20 – Printing area: 107 x 200 mm

SWING XL 4.40 – Printing area: 107 x 400 mm

SWING XL 4.60 – Printing area: 107 x 600 mm

SWING XL 5.09 – Printing area: 128 x 90 mm

SWING XL 5.20 – Printing area: 128 x 200 mm

SWING XL 5.40 – Printing area: 128 x 400 mm

SWING XL 5.60 – Printing area: 128 x 600 mm

APPLICATIONS

TECHNICAL SPECIFICATIONS

- Printing width: 107 mm or 128 mm.

- Printing length: from 90 mm to 600 mm.

- Printing definition: 12 dots/mm (300dpi)

- Printing speed: up to 400 mm/s (on plastic film) and up to 250 mm/s (on paper film).

Download