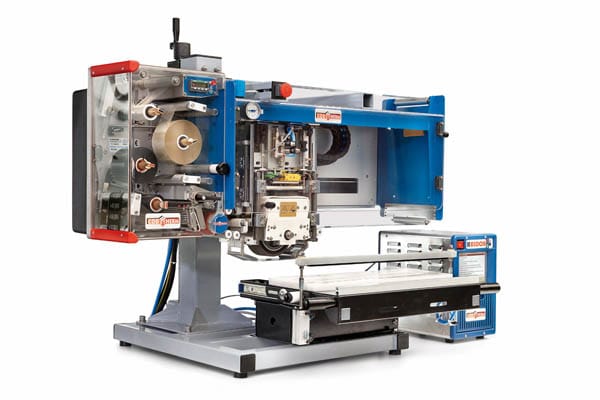

CODITHERM, PRINTING EXCELLENCE

Coditherm printers are designed in the Eidos research and development workshops to implement the advantages of digital printing flexibility on industrial products. By implementing clean and environment-friendly methods, Coditherm can be used to print small batches with variable data (dates, forward or backward number sequences, texts, lists of ingredients, barcodes, two-dimensional codes, logos) directly on plastic surfaces, porous materials, irregular substrates, rigid and round objects without interrupting the production process and guaranteeing object traceability.